Copyright © 2024 AllCases, Reekstin & Associates, Inc.

Website and Marketing by WD Morgan Solutions

Copyright © 2024 AllCases, Reekstin & Associates, Inc.

Website and Marketing by WD Morgan Solutions

Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold. The process begins with taking the polymers in the form of pellets or granules and heating them to the molten state. The melt is then injected/forced into a chamber formed by a split-die mold. The melt remains in the mold and is chilled down to solidify. The mold is then opened and the part is ejected.

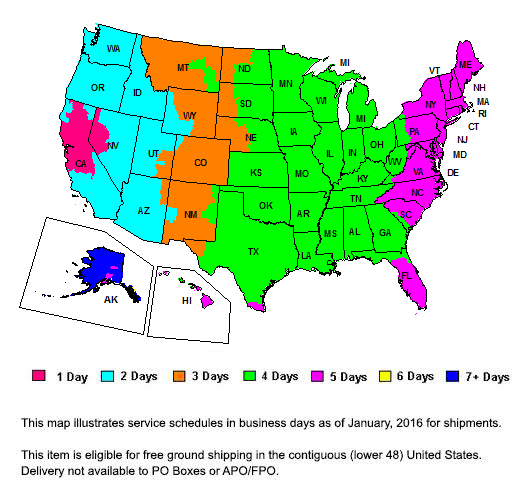

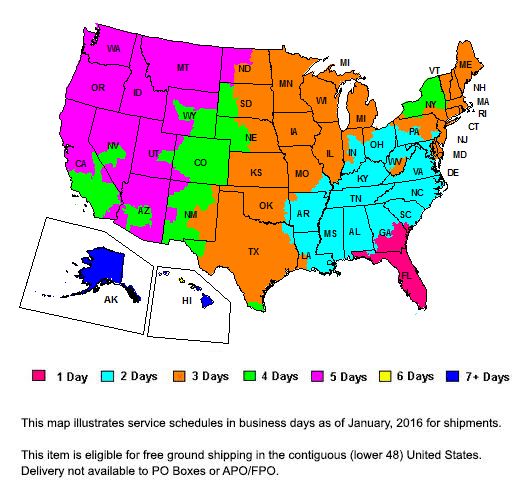

Stock Cases: Injection Molded Cases are off-the-shelf cases, and can typically ship ‘as-is’ in 1 – 3 business days.

View Certs and Testing

Pelican and Pelican Storm Case Catalog

Pick N Pluck Foam Instructions