Copyright © 2024 AllCases, Reekstin & Associates, Inc.

Website and Marketing by WD Morgan Solutions

Copyright © 2024 AllCases, Reekstin & Associates, Inc.

Website and Marketing by WD Morgan Solutions

Plastic sheets are placed in an oven for heating so that they become pliable. The heated sheet is then placed over a form (shaped like your end part) and a vacuum is then applied to remove trapped air and to pull the material into or onto the mold along with pressurized air. This then forms the plastic to the detailed shape of the mold. After a short form cycle, a burst of reverse air pressure is actuated from the vacuum side of the mold as the form tooling opens, commonly referred to as air-eject, to break the vacuum and assist the formed parts off of, or out of, the mold. Thermoformed cases are available in stock or customizable options.

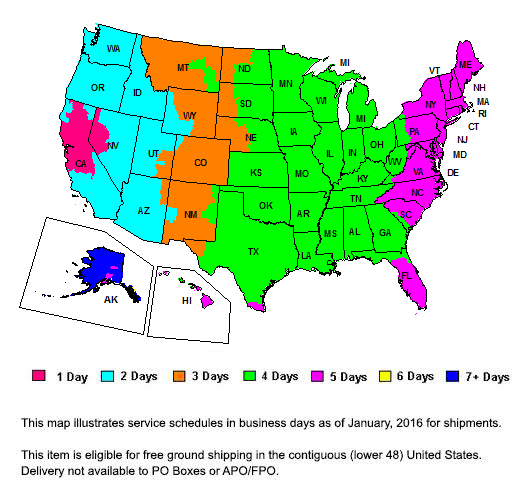

Stock Thermoformed Cases are typically shipped ‘as-is’ in 1-3 business days.

Medium Duty Rolling Case Size Chart

Light Duty Rolling Cases Case Size Chart

Rugged Shipping Case Size Chart

Rugged Shipping Cases – Rolling Size Chart

Rugged Shipping Cases – Rolling with Scoping Handles Size Chart

Extra Heavy Duty Tote Case Size Chart

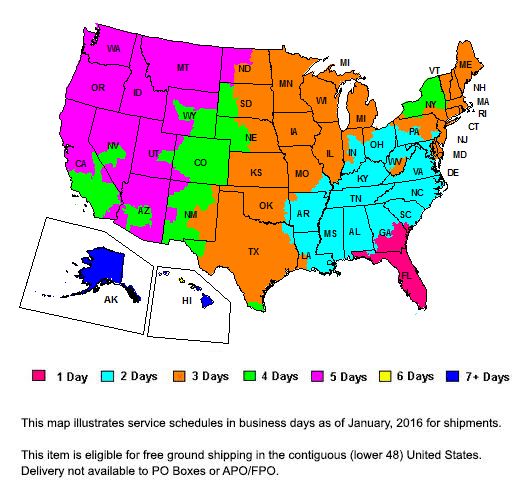

Customizable Thermoformed Cases are built to order, allowing for custom add-ons, and typically ship in 2-6 weeks.

Expo Transport Cases Size Chart

Heavy Duty Aerospace Cases Size Chart

Heavy Duty Shipping Cases Size Chart

Light Duty Carrying Cases Chart

Medium Duty Carrying Cases Size Chart

Medium Duty Carrying Cases Size Chart

Medium Duty Carrying Cases Size Chart